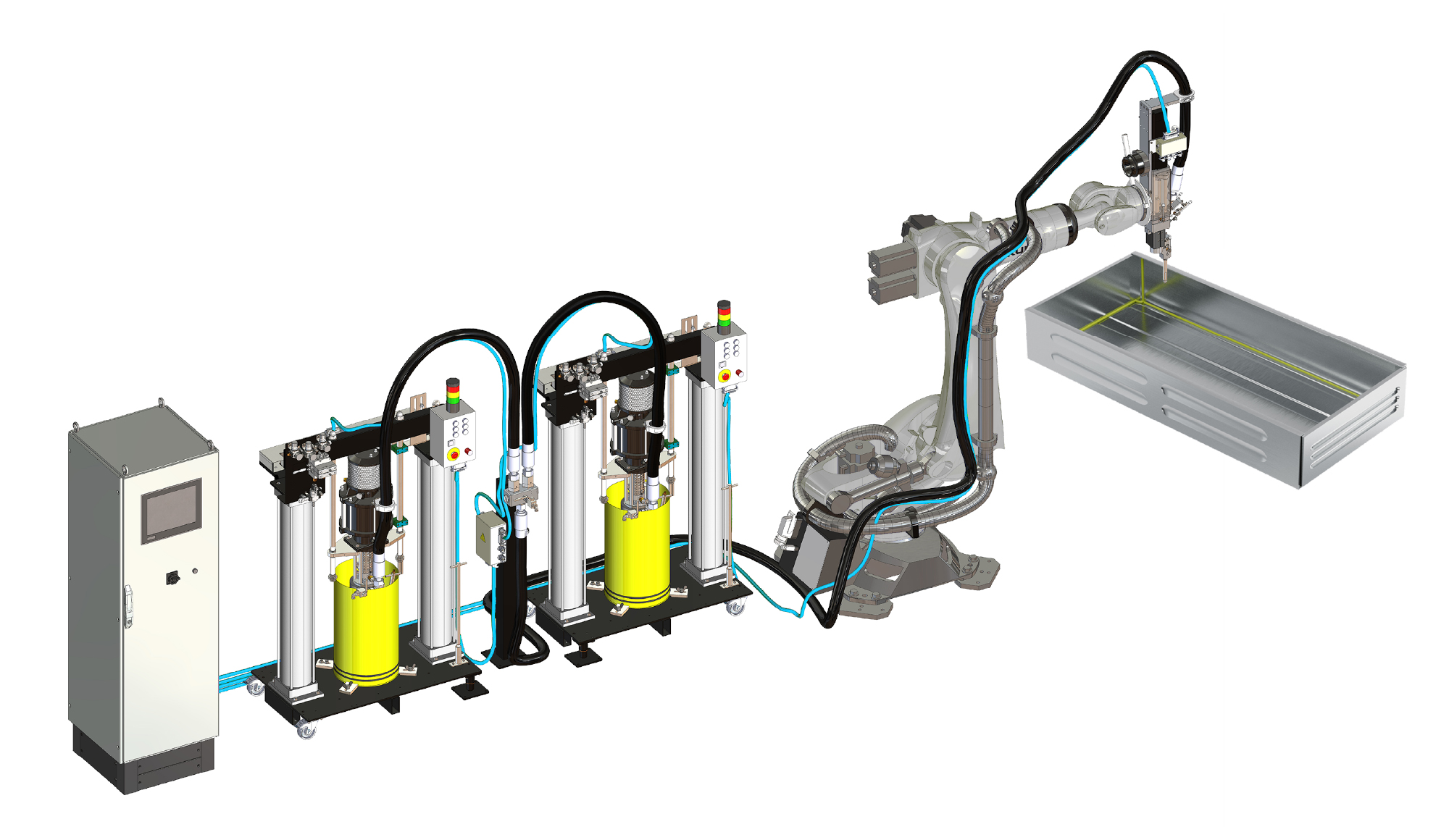

Cell structural bonding with large shot meter

Accurate & secured dispensing of adhesive on battery cell for a robotic manufacturing process

The robotic system dispenses 1K adhesive accurately with an electrical shot meter, using a FiFo (First In / First Out) setup to avoid dry material sticking inside. The dosing unit design makes it fast & easy to change any component for maintenance teams.

The control cabinet manages the dosing unit, the dual ram unit pumping station, and any heating zone required to maintain material viscosity stable during dispensing.

Last but not least, the vision system secures your application process by monitoring all process data linked to the real adhesive bead on parts.

Perfect quantity and position of adhesive

Repeatable application by robot

Ensure uninterrupted operation with continuous material supply from a dual-ram unit

Monitor your application with the vision control system

All 1K adhesives on the market—fully compatible. Thanks to our close collaboration with material suppliers, Sames’ pumping and dosing equipment is compatible with all 1K adhesive products available.

Your adhesive solution must be both robust and reliable. To ensure precise dispensing, our FiFo canister system detects air bubbles in the adhesive before application. During the process, our integrated camera system monitors the bead in real time—identifying any missing material, misalignment, or shape defects. If an issue is detected, alerts are triggered immediately.

When it comes to reliability, our heavy-duty components are built to last. With a durable design, minimal spare parts, and easy maintenance, your equipment delivers long-term performance and uptime—exactly when and where you need it.

Managing 2K adhesive materials starts with selecting the right dosing unit based on volume and mixing ratio. Servomotor-driven units feed a static mixer with high precision to ensure proper adhesive behavior. For low volumes, compact units can be mounted on the robot; for high volumes, dosing units stay on the floor while the mixer is placed near the nozzle on the robot head. This set-up ensures accurate mixing and efficient application across different production needs.