PVDF lacquering with electrostatic rotary bell

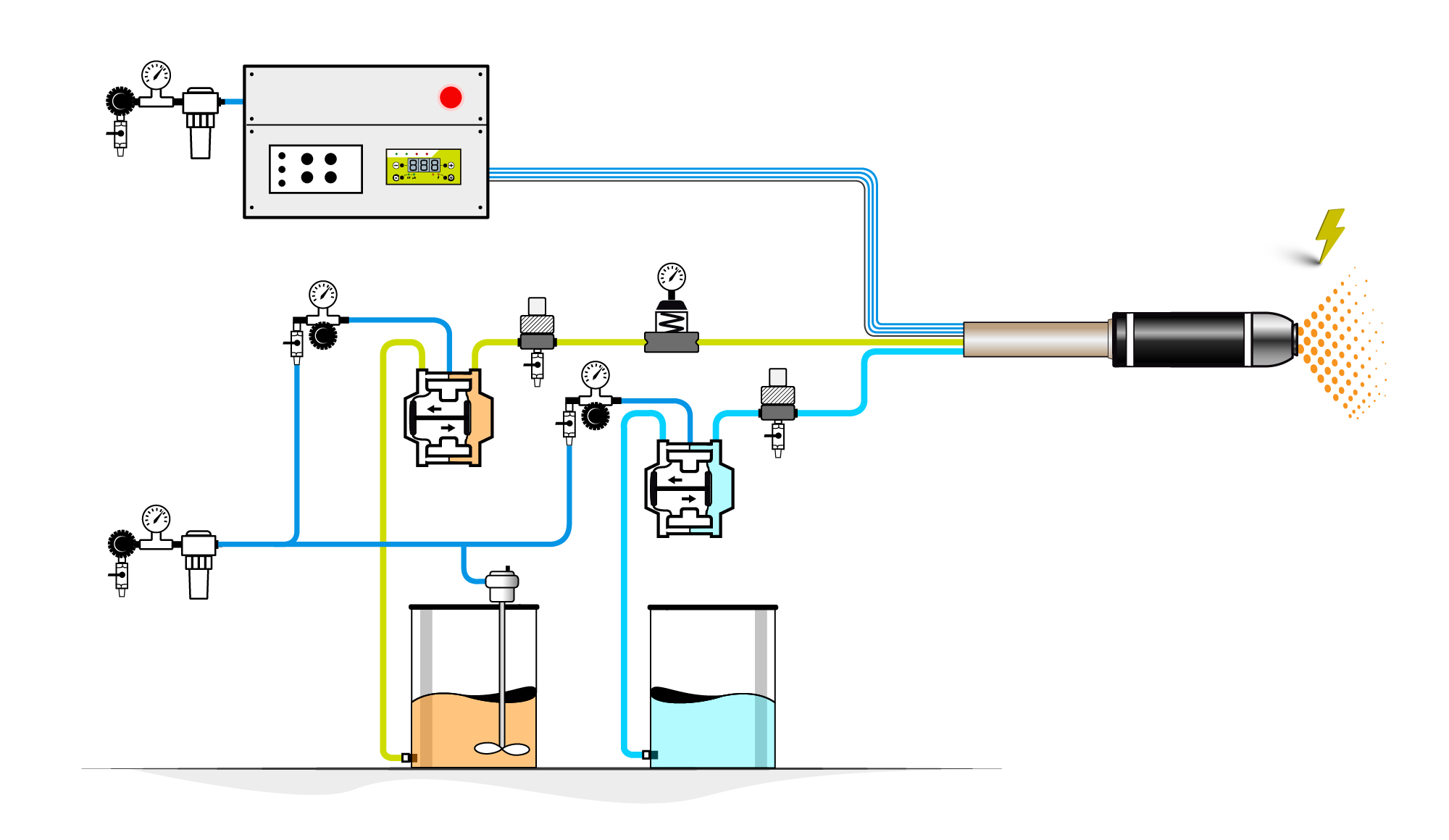

Automate, save up to 50% of paint, 30% of cycle time and obtain better finishing quality with Sames Nanocoat robotic electrostatic rotary bell spraying combined with 2K antenna.

For corrosion protection of aluminum profiles, the choice of coating process such as liquid PVDF or thermo-lacquering with powder mainly depends on the level of finish and durability required by the customer.

PVDF liquid coatings are typically chosen when premium weathering and color retention are essential. Sames offers robust industrial solutions for PVDF liquid applications, with extensive experience in designing complete installations tailored to specific production capacity requirements. These systems include optimized color-change architectures that integrate color-change blocks located close to the spray bell, enabling quick and efficient transitions between shades.

The latest evolution in Sames Nanocoat rotary bell technology, the Nanobell 803 Straight, brings approximately 10% improvement in transfer efficiency over its predecessor, the PPH308, thanks to innovations such as NW shroud and Hi-TE bell cups.

For thermo-lacquering processes, Sames also provides a comprehensive offer based on powder coating technologies. This includes not only traditional electrostatic spray guns, but also the unique Inobell rotary bell, which ensures outstanding finish quality and powder savings. In addition, key components such as the Inocenter powder feed module.

Through these technologies, Sames brings integrators the opportunity to offer premium brand process solutions, helping customers meet both aesthetic expectations and operational efficiency goals across their aluminum coating applications.

Efficiency: Up to 35% paint savings and reduce application time compared to non-electrostatic methods.

Simplify application, achieve very even coating thickness and good coverage including hidden parts, thanks to Sames powerful electrostatic effect.

Productivity: Automate your coating process and boost production capacity by more than 30%.

For high-volume PVDF coating on aluminum profiles, electrostatic rotary bell spraying is the most effective technology—offering top transfer efficiency and certified finish quality for architectural standards.

Sames' Nanobell 803 builds on the proven PPH 308 platform, adding features like the Narrow-Wide (NW) shroud for better coverage on varying profile shapes. This ensures consistent film build, excellent edge coverage, and adaptability—ideal for continuous lines with reciprocators.

With high precision, repeatability, and compliance with Qualicoat and GSB International standards, Sames rotary bells are a premium, reliable solution for PVDF coating applications.

PVDF coatings are almost exclusively applied as liquid paints due to their superior UV resistance, durability, and compliance with top certifications, like QUALICOAT Class 3 and GSB Master. Powder-based PVDF exists but faces technical challenges—such as poor flow, high curing temps, and inconsistent finish—that limit adoption and certification.

However, non-PVDF powder coatings are widely used and suitable for less demanding specs (e.g., QUALICOAT Class 1/2, GSB Standard).

For powder applications, Sames' Inocoat range offers complete solutions—manual, automatic, or robotic—with proven expertise across both powder and liquid technologies.