Protective coating of seamless steel pipes

Implement VOC-free paint systems for protective coating of seamless steel pipes in heavy industry environments.

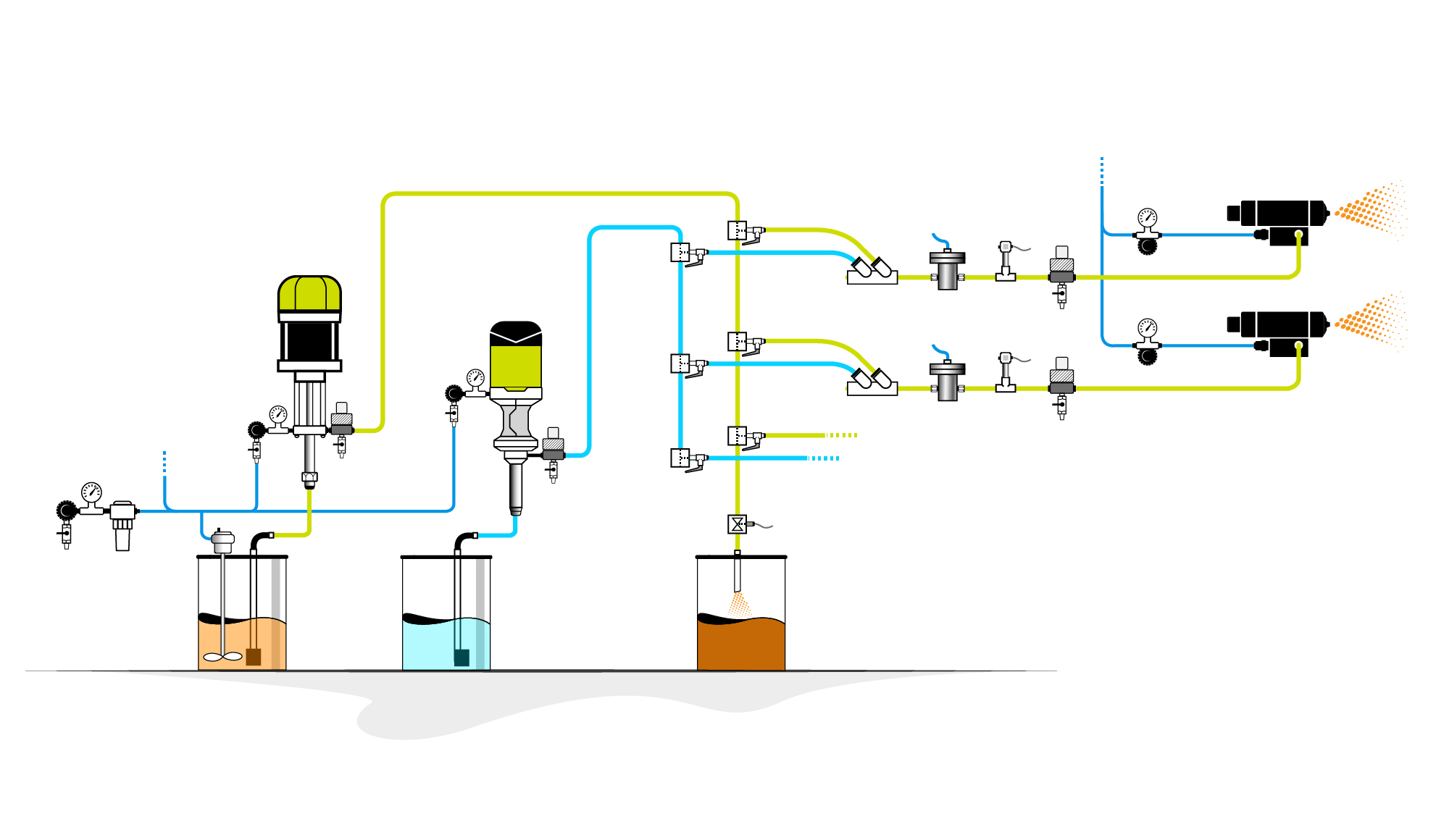

The long tubes (approximately 13 m) are conveyed one by one under a ramp of 4 to 6 Airless ASB240 spray guns. They are then rotated while the guns move longitudinally spraying the single-color protective paint. This paint had been previously transferred with a diaphragm 04D140 pump from delivery packaging to the preparation tank in the paint kitchen, then agitated and brought to CTM valves located close to each consumption point by means of a high-pressure pump 30C980. Regsmart paint pressure regulators near each sprayer allow the system to be balanced. Finally, at the end of the production sequence, a purge recovery system allows the circuit paint and cleaning solvents to be connected. The entire paint preparation tank, paint circulation pipes, and airless sprayers are protected from freezing by means of electrical tracing solutions.

Spray VOC-free WB sensitive paints in non-climate-controlled spaces during the coldest winters months

Designed for harsh environments

Easily servicable

To ensure consistent paint flow across all sprayers—especially when multiple guns are used—several elements are critical:

Regsmart pressure regulators placed near each ASB 240 Airless spray gun provide precise control at the point of use, ensuring uniform flow despite circuit variations.

A 30C980 high-pressure pump with continuous circulation and tank agitation maintains steady pressure and paint consistency.

Reversible tips allow quick clearing of clogs, minimizing downtime and keeping flow stable.

Preventive maintenance and daily/weekly cleaning routines (including purge recovery) ensure long-term consistency by preventing buildup and equipment wear.