Spray 3K-WB primer coating with manual Airmix gun

Save up to 30% of paint, 25% of cycle time, and obtain high finishing quality with Sames Xcite®+ manual gun spraying combined with automatic mixing technology.

In the demanding world of aerospace, precision and process control are non-negotiable. Sames offers a complete 3K (three-component) paint application solution, engineered specifically for aeronautic structures, where pot-life management, traceability, and flawless finish are critical.

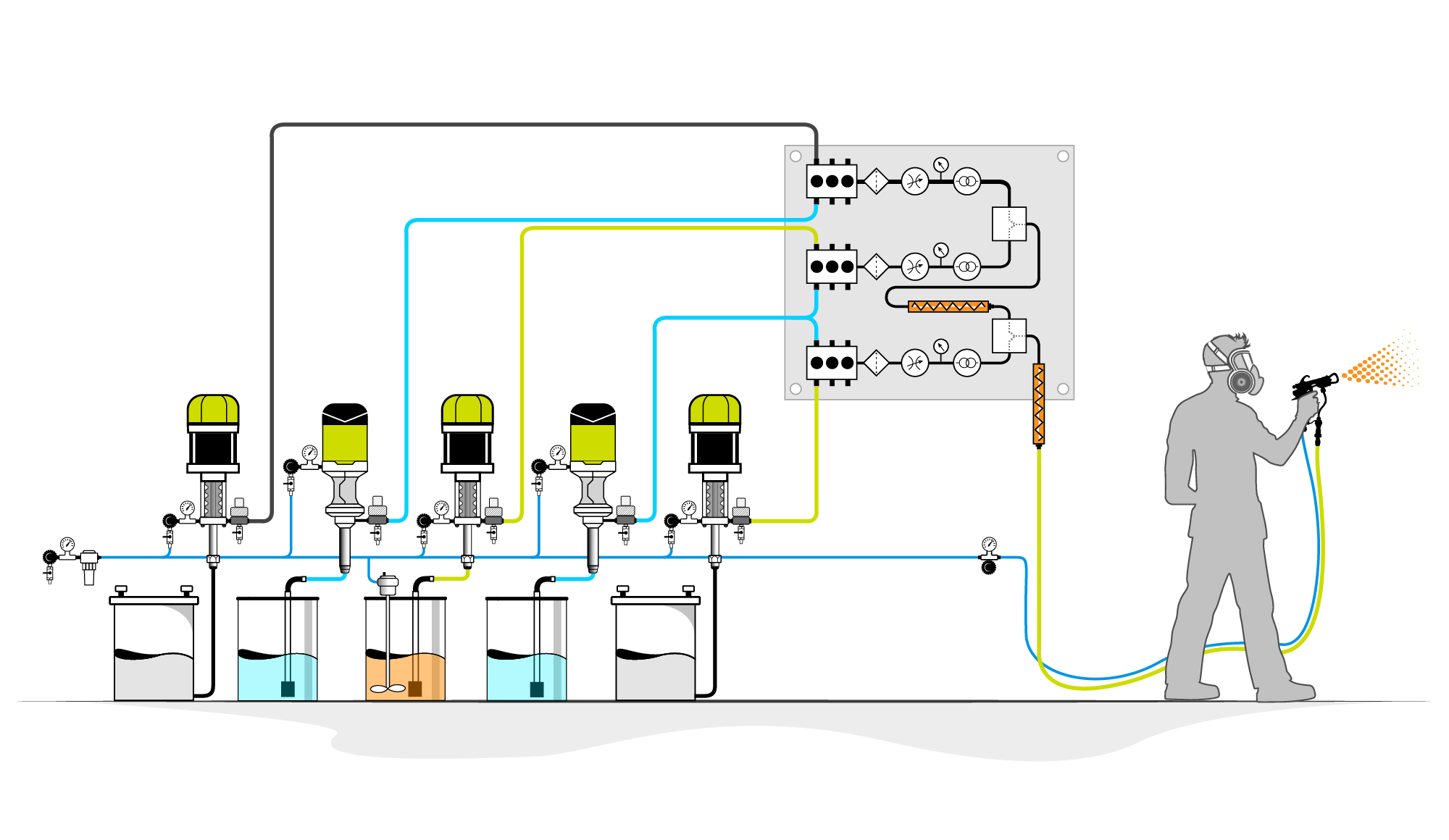

Our solution features:

Flowmax® below pump technology for moisture-sensitive hardeners.

The Cyclomix® Evo 3K automatic mixing machine, which regulates pressure, manages mixing ratios in real time, and ensures consistent quality throughout the application.

Spraying with manual Airmix® Xcite®+ gun, combining outstanding finishing quality with high transfer efficiency and productivity — making it the go-to reference for demanding aeronautic coatings.

Semi-automatic flushing box, which automates flushing and mixing refresh cycles, keeping the mix age below the defined pot-life.

With the arrival of new chromium VI-free primers that feature shorter pot-life windows, automated 3K mixing is no longer optional — it’s essential.

The Cyclomix® Evo 3K also supports digital traceability and data logging, aligning with the aerospace industry's digitalization and quality assurance standards.

Better finish quality with a fresh paint mix and superior atomization from the electrostatic system.

Minimize paint and solvent waste: Mix only what you spray. Up to 50% waste reduction during paint preparation and color changes.

No more rework: Eliminate mixing errors with precise automatic proportioning and mixing operations with 2K mixing machine.

No, it's not recommended to use the same mixing and spraying equipment for both epoxy primers and polyurethane topcoats due to chemical incompatibility between their hardeners. Separate circuits or strict equipment isolation must be considered to avoid cross-contamination and ensure finish quality.