Spray 2K paint with Airmix® manual gun

Save up to 30% of paint, 25% of cycle time and obtain high finishing quality with the Xcite®+ manual gun spraying combined with automatic mixing technology.

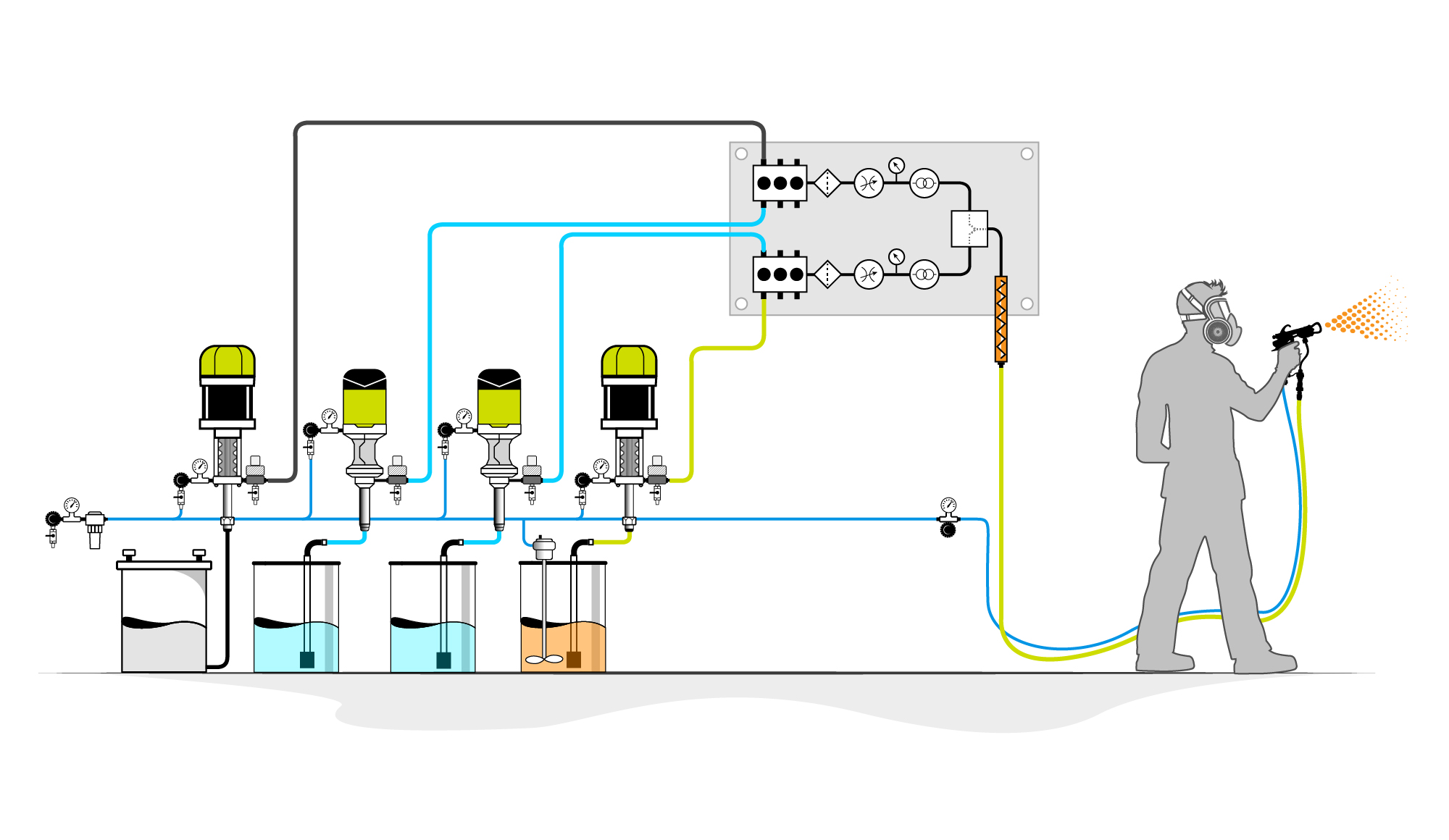

Paint and hardener are pumped and mixed fresh during spraying. Airmix® technology ensures efficient atomization and coating with viscous paint. The 2K unit automates pot-life control, color changes, purging, and cleaning.

Colors are pumped to the color-change valve block by piston pumps drawing paint from the original drums. Drums can include a paint agitator to prevent sedimentation, and paint can be heated to reduce viscosity. The hardener is pumped from a sealed tank using the Flowmax® pump, which is fully sealed to prevent humidity contamination.

The 2K mixing machine proportions and mixes only during spraying to ensure fresh, homogeneous paint at the gun. During application, the Airmix® gun atomizes paint through a straight pressure drop and completes atomization with a limited amount of air.

Airmix® technology allows spraying a single thick layer of high-viscosity, thixotropic paints. The 2K unit monitors pot-life and provides fully automatic color change, purging, and cleaning operations.

Productivity: Spray a single thick layer of viscous paint with Sames Airmix® technology.

No more rework: Eliminate mixing errors with precise automatic proportioning and mixing operations with 2K mixing machine.